Lessons Learned – by Pat Carson

Winter is Coming…

By the time you read this edition, winter will be just around the corner; and will your boat be ready? If you keep your boat on a trailer or on a HydroHoist, you will need to prepare for the possibility of freezing temperatures. For those that keep their boats in the water over the winter, freezing temperatures are not so much the issue. However, the cold takes its toll in other ways, therefore you still need to prepare.

A few years ago, I was contracted to move a 25-foot trailer boat from the Midwest to California. The owner had moved to California two years earlier and his boat remained behind in dry storage, and it was now time to bring the boat to the Delta. She was a very clean and well cared for 10-year-old cruiser, but as you can imagine, two years of storage and neglect, along with a cross country road trip had left her dirty and in need of some serious clean up and maintenance.

Once the boat had arrived in California, a thorough inspection ensued and we formalized our plan of attack. A fresh change of the fluids, start it up, take it out for a sea trial to see how she runs and then do a complete detail on both the interior and exterior. Before we began, we sampled the fuel and found an abundance of water in the fuel tank and the gas appeared to be separated; a combination of a tank level at 33% and Midwest alcohol blended fuels don’t age well! The engine oil looked OK, but oil sample analyses revealed a high level of moisture and confirmed a needed oil change. The outdrive had not been serviced before layup, so we planned a complete service on it. This engine is raw water-cooled, therefore no coolant to mess with making it a bit easier. Although raw water-cooled marine engines are common for boats not expected to see salt water; the downside is you must be sure to winterize the engine given that it circulates merely water throughout the engine block and offers no freeze protection.

As one of the mechanics was servicing the outdrive, the other was inside the cockpit pumping 40 gallons of rotten gasoline from the tank. With the fuel extraction pump working hard we were preparing to change the engine oil when the mechanic finds a round metal plug in the bilge under the engine. It is quickly identified as a freeze plug and its home on the engine block is found just as fast.

Engines have many freeze plugs to help prevent water that is cooling and expanding from cracking the block or heads. The plug will hopefully give way first and allow the water a place to go. However, it is not a good sign that the engine had enough raw water in it and that it got cold enough to force one of the 14 or so plugs out. The engine was inspected as best we could as it was shoehorned into the small, cramped engine space and had all the accessories on it. With no obvious freeze damage found we continued with the oil and fuel changes. The discovery of the engine freeze plug made it necessary to inspect the outdrive closely as it also has raw water inside that can freeze and cause damage.

The next day with a new battery installed, fresh fuel in the tank, the engine fluids changed and the outdrive inspected and serviced the engine was ready to be started. With only a bit of coaxing, it fired up but ran rough. We surmised it might need a complete tune-up after all. After approximately ten minutes of running, a white gooey fluid started to flow from engine orifices that are not supposed to have fluids in them. We shut down the engine and quickly determined that the crankcase had not only oil in it, but a substantial amount of water, and the two were mixing and creating the white gooey milkshake. There were telltale signs that either the head or the block was cracked from freezing water, and I was not looking forward to making the phone call to the owner. There really was no choice but to pull the heads and determine where the crack might be and whether this engine can be saved. A few hours later with the heads off, the cracks were obvious in the block. Unfortunately, this engine cannot be saved and after pulling it out of the boat it was now easy to see the substantial issue.

Proper winterization is very important as this owner found out the hard way. Although we don’t get many days where the temperature dips into the 20’s, we do get a few. According to one insurance company’s statistics of all the 50 states, California has the most winterizing claims. In a temperate state like California, freezes do not occur often so we do not always take preparations seriously. In the Midwest they start pulling boats from the marina around Labor Day, winterize them, shrink wrap them and then store them on shore. But freezes do happen in our area and boats stored surrounded by air are much more vulnerable to freeze damage than boats surrounded by water.

Preparing your trailer boat for winter can be a do-it-yourself project. In less than a few hours you can take the worry out of winter storage, however, there is more to winterizing a boat than just draining water from the engine and adding stabilizer to the fuel. The exterior needs to be prepared as does the interior, and don’t forget the fresh water and sanitary systems. Thinking that you will just place a space heater inside the boat and in the engine room instead of properly winterizing the boat, do not do it. Every year unattended heaters cause fires. Heaters are no substitute for proper winterization.

The seven basics of winterizing small boats on a trailer or lift are:

1. Treat the fuel – any fuel with ethanol will phase separate during storage if left untreated. Add stabilizer per the manufacturer’s instructions and then run the engine long enough to get treated fuel throughout. The fuel tank should be stored completely full of treated fuel. With a full tank there is limited space for moisture to condense. If the fuel has already phase separated adding stabilizer will NOT help. Once fuel has separated the only solution is to remove it and start with fresh gasoline – preferably with no ethanol.

2. Drain the old lube oil from the engine and put in new oil. If you have an outboard engine, drain and refill the lubricating oil in the gearcase as well.

3. On your outboard engine or sterndrive check the prop shaft. Remove the prop and clean any fishing line or other foreign objects from the shaft. When replacing the prop be sure to apply a bit of marine lube on the hub.

4. Apply a high-quality marine grease to any Zerk fittings.

5. Check and fill trim fluid for your outboard or stern drive boat. Inspect the color of the fluid for any signs of water intrusion.

6. Do not forget to check the batteries. Boats have many DC-powered systems that may have separate battery banks. Thrusters, inverters, engine start, house, generator start, can and often are separate and dedicated systems. If you have flooded electrolyte batteries make sure the electrolyte is full by adding distilled water. If you plan to leave a battery charger connected and powered on during the off season it should be a smart charger so that the batteries are not overcharged. Flooded batteries need regular maintenance and should be checked monthly even if you are not using the boat. If you do not leave a charger connected, some batteries will self-discharge at 10% per month.

7. Clean the boat inside and out. If there is water or other fluids in the bilge, now is a `good time to clean the area.

Every boat is different. Check and follow the manufacturer’s specific instructions for off season layup recommendations and procedures.

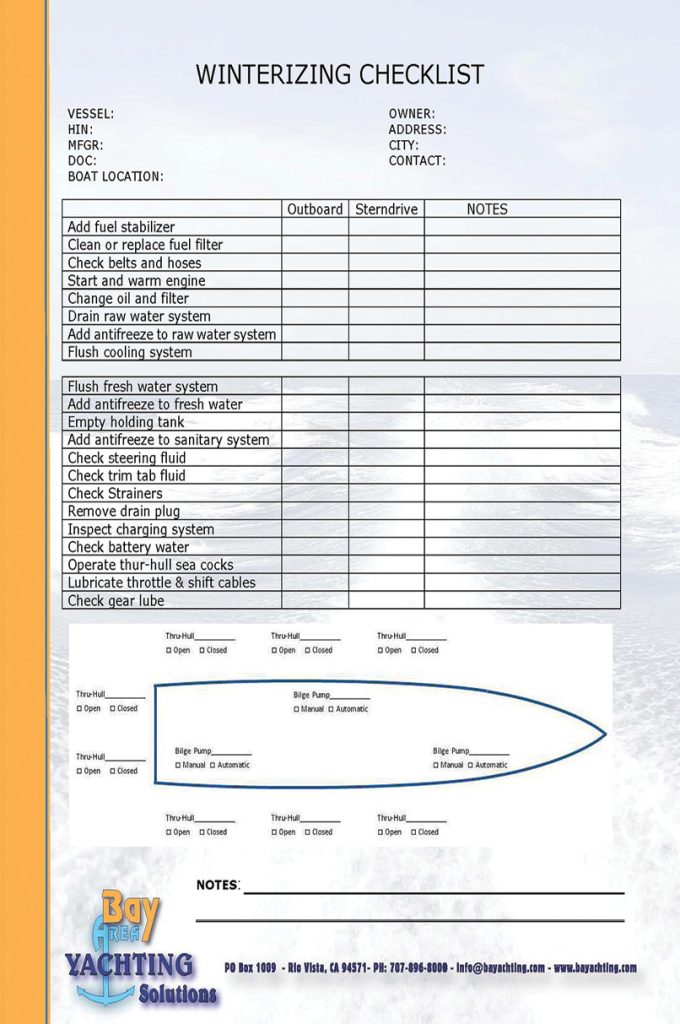

We have a checklist that we use to winterize boats in the Bay and Delta, and it is available for download. You can use this as a guideline on the items that should be addressed. The link is: http://www.bayachting.com/winterizing

Don’t have a trailer boat and your yacht stays in the water year-round? You still have a few winterizing chores that will protect your boat. That engine oil that has been there all year has most likely accumulated acids and deposits. Unless you regularly start and run the engines up to operating temperature, that old oil will cause premature wear to the internal parts of the engine. Changing the oil now is better than waiting until spring. Fresh water systems can and do freeze, possibly causing pipes and tanks to crack. A good nontoxic freshwater antifreeze added to the system will prevent that from happening.

There are several different products available at the local chandlery. Be sure to follow the manufacturer’s guidelines for the correct concentration and flushing procedure. Don’t forget the hot water tank. Most of us keep our hot water tank powered off when not on the boat, and the water in there can freeze unless emptied or treated. The sanitary system also has fresh water in it. That should be drained, and an antifreeze/lubricant should be added. Consult with the manufacturer for their recommended winterizing product. Some of these chores can be avoided by installing a properly sized engine room heater.

While you are taking care of possible freeze problems, now is a good time to check the other systems. If you plan to be away from the boat for extended periods of time, check to be sure that bilge pump automatic sensors are working properly. Inspect the thru-hull valves for evidence of water leaks and galvanic corrosion and make sure the valves operate easily. Consider leaving them in the closed position, but if you do be sure to put a warning at the helm that the seacocks are closed so that someone, maybe even you, does not start the engines with closed seacocks. Check the dock lines for wear and add an additional one or two; I like to have a line on every cleat. To keep the mold and mildew at bay, put a dehumidifier in the interior spaces or set your reverse cycle heat and AC system to “dehumidify” mode. Be certain the power cord is securely attached at both ends and tighten down the watertight seal ring. Check the battery water and the battery charger for proper operation. Finally, make sure the harbormaster has your current contact information.

Lessons Learned

Two weeks after we found the cracked block, we have a new engine installed, the outdrive serviced, all systems checked and the exterior and interior detailed. It’s time to launch the boat and go for a test drive, my favorite part. No surprises here, she looks good and runs even better. The owner has a boat that looks and runs like new and is quite pleased with the result, but not as happy about the expense.

Having stored his boat in an inside dry storage facility did not protect the engine from freezing. When there is a power failure, that heated indoor facility can get cold quickly. We all agree that this was an unfortunate occurrence for the owner. With a little more preparation and proper winterizing, his expense would have been much less. That little bit of neglect to properly prepare for winter and relying on the storage facility to keep the boat warm resulted in having to buy a new engine costing many thousands of dollars.

With the boat back on the trailer and the keys handed over to the harbormaster at the dry storage facility, it is time to sit back and enjoy a cigar and glass of port while I am thinking about winterizing the tender stored high up on the boat deck of the yacht. The lesson here is that you might get away with not properly winterizing your boat and you might not. If you do not, it may get very expensive. Keep those letters coming and if you have any photos to share, please send to patcarson@yachtsmanmagazine.com