Lessons Learned – by Pat Carson

Fuel Management

As I write this article in the early part of July, we are at the peak of the offshore boat delivery season and this year has been more challenging than most. With the weaker than usual Pacific highs not pushing the low-pressure systems back to Alaska where they belong, the sea conditions along the Northern California coast have been rough. I get a lot of calls and messages from other delivery captains and some boat owners that are considering having their boats moved to Washington for the summer, wanting to discuss the weather forecasts and potential timing for a coastal voyage. An equally important consideration after weather forecasting for voyage planning that not everyone considers is fuel management. Since sea conditions can greatly affect the fuel economy of a vessel and sea conditions can vary greatly throughout the day (or night) careful consideration must be given to fuel management.

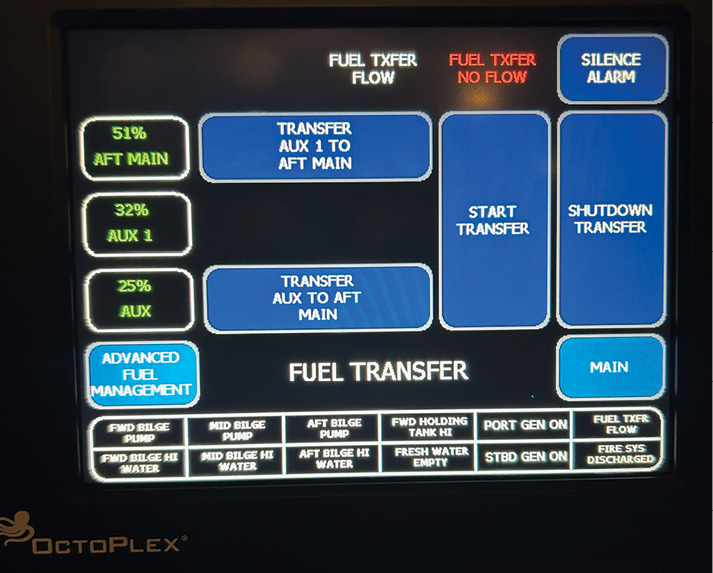

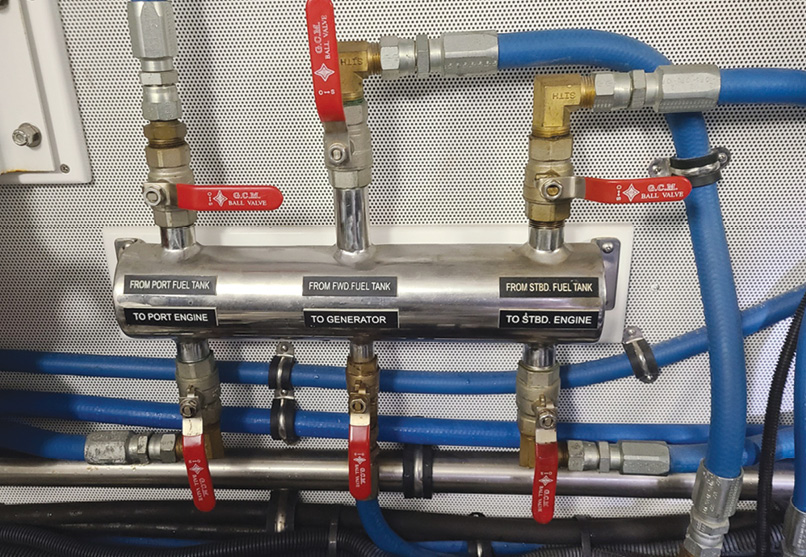

When putting together my voyage plan for a late model Viking 70 going from Seward, Alaska to San Diego, California you can imagine our tolerance for adverse weather is greater than it would be for a smaller, less ocean capable vessel but even a renowned big water fish killer has it limits. My biggest concern is that the vessel carries just 2,300 gallons of diesel in three tanks and fuel is transferred by a single electric pump controlled via an electronic touch screen. The owner’s regular captain and crew are bringing the vessel from Seward to Seattle and our crew will take over from Seattle to San Diego. This plan allows for two days with the other captain to get familiar with the vessel and make preparations to get underway. Top of my list of questions all have to do with fuel management and fuel economy at various engine speeds. Once we understand the normal operating conditions regarding engine RPM, Speed Over Ground and fuel burn rate we can then start to make a preliminary plan of daily distance to be covered, planned fuel stops, and estimated time and dates of arrival. As a starting point we use the captain’s usual SOG of 24 knots, fuel rate of 120 Gallons Per Hour, the main tank holds 1,100 gallons, the mid aux. fuel tank holds 650 gallons and the forward aux. fuel tank holds 550 gallons. These capacities are confirmed by checking the actual tank capacity labels where there are usually two numbers, one is maximum capacity and the other is usable capacity. Not surprisingly, I have seen a difference of as much as 5% between the two numbers and almost always some marketing puke quotes the “fuel capacity” as the larger of the two numbers, and if they had to convert from liters to gallons, they always round up!

Based on the above data for this particular vessel, we can expect a range between fuel stops of approximately 400 miles with a planned 20% reserve. Ah, but not so fast, remember that this boat has three tanks, the main tank is only 1,100 gallons and there is no fuel management manifold, merely a single electric pump to move fuel around. We need to plan on having only the fuel in the main tank available in the rare case the fuel transfer system becomes inoperable. This means that we need to plan an emergency fuel range of only 175 miles. The main tank of 1,100 gallons with a 20% reserve allows a usable capacity of 880 gallons. At 120 GPH we can run for a little over 7 hours at 24 knots. Now there is always the opportunity to slow down to a more economical speed if needed, however, when you take weather conditions into account, we plan our voyage for normal SOG although consideration is always given to slowing if weather forecasts allow a longer runtime.

With vessels configured in such a manner, we will always transfer fuel from the smallest tank to the main tank at the earliest opportunity. In this vessel we moved the 550 gallons from the forward aux tank when the main tank was just under 50%, thereby adding approximately 4.5 hours of runtime or roughly 110 miles. We could then decide when and how much fuel to transfer from the larger mid aux tank to reach our intended refueling destination.

When we left Seattle Lake Union on Monday, June 10, we had an absolute must be delivered date of 1200 on Wednesday, June 19. Ten days seems like more than enough time, but as I mentioned earlier weather and sea conditions this year have been unfavorable to nonstop coastal voyages. Having departed Lake Union with full fuel we made our first fuel transfer after approximately 120 miles just after rounding Cape Flattery. We made our second fuel transfer just south of the Columbia River and arrived at our planned fuel stop in Yaquina Bay with a reserve of nearly 25%. Day two went equally well as we secured the vessel in Humboldt Bay where we planned to wait out the forecasted horrible weather at Cape Mendocino. After a four-day delay in Eureka, which was not all bad since the owner of the RMF Boat Yard, Tod Reincke, was available to attend to a few minor issues and graciously performed daily checks on the vessel, we were back underway intending Monterey as our next fuel stop.

Returning to the vessel on June 15 we now had just 4.5 days before our deadline of June 19. Fortunately, we were able to keep to our voyage plan with fueling stops in Monterey and Long Beach and arrived in San Diego at 1700 on June 18, a full 19 hours ahead of deadline.

The next boat relocation was just the opposite of the Viking 70, this as a 45-foot sport yacht that had a cruise SOG of 28 knots but in calmer waters. The fuel capacity of 280 gallons in a single tank was also less but appropriate for a vessel of this size. Here again I checked the tank label, and it was marked as a capacity of 1,100 liters with a usable capacity of 1,060 liters, a nearly 4% difference. Of course, the advertising listed a fuel capacity of 290 gallons but more disturbing is that the electronic fuel monitor indicated a full tank with 290 gallons. After correcting their programing error, we had a range at cruise speed in calm water of somewhere in the neighborhood of 160 nautical miles before reaching the real 20% reserve. This shortish range forces our voyage planning to be very different than the big Sportfisher. In this case we planned fuel stops in Port Angeles, Grays Harbor, Yaquina Bay, Brookings, Humboldt Bay and Bodega Bay. Arrival timing is critical since these planned fuel stops only offer the availability of after hours fueling at Grays Harbor and Yaquina Bay. As a backup, if needed, we could change our route plans and get after hours fueling in Coos Bay or Crescent City.

As part of managing fuel, you have to figure out how you are going to make the 190-mile leg from Humboldt Bay to Bodega Bay since fueling a boat in Noyo River requires scheduling a fuel truck 48 hours in advance and there are no other fuel stops along this part of the California coast. The answer, of course, is to slow down and increase your miles per gallon, however, there are times when this is not reasonable due to sea conditions. Again, careful planning and proper fuel management are as important as weather forecasting.

Next month in part two, I will share another short story where even with proper fuel management, things did not go quite as planned. Until then, let me wrap this up with a few guidelines and the importance of understanding the intricacies of your yachts’ fuel management system whether you are planning a weekend cruise around the Bay and Delta or something more adventurous that takes you along the coast.

Regular Maintenance Matters

Your yacht’s engine longevity is closely tied to how well you maintain its fuel system. Regular checks are key. Here is what to focus on. Inspect fuel lines for cracks or leaks. Damaged fuel lines can lead to contamination or blockages, affecting engine performance. Check and replace fuel filters as needed. Clean filters ensure plenty of clean fuel reaches your engine.

Quality Fuel Is Non-Negotiable

Contaminated fuel is a yacht’s nemesis. Always refuel with high-quality, clean fuel. It is like giving your yacht a spa day – it will thank you with smoother sailing. Store fuel tanks full to prevent moisture absorption and the resulting biological growth inside the tank.

Embrace Modern Technology

Digital fuel-flow meters are your fuel system’s BFF. They monitor and report real-time fuel usage, helping you optimize consumption. GPS navigation is not just for finding that hidden cove, it also ensures you take the most fuel-efficient routes.

Weight Distribution And Hull Maintenance

Distribute weight evenly. Proper weight distribution minimizes drag, which translates to better fuel economy. Regular hull cleaning keeps your yacht sleek and slippery through the water and less resistance means less fuel burned.

Plan Efficient Routes

Use navigational tools to chart the most efficient course. Avoid zig-zagging – unless you are dancing on deck, of course! Remember, efficient fuel management is not just about saving money; it is also about reducing your carbon footprint and ensuring smoother, longer journeys. So, treat your yacht’s fuel system like a VIP guest – give it the care it deserves.

Fueling a boat is not like fueling a car. With our cars we pull up to the pump, put the nozzle in, pull the trigger, and walk away to make phone calls or just get out of the weather. The pumps click off when we are done, sometimes we squeeze the trigger a few more times for good measure, and we put the nozzle away and leave. Easy and safe. Unfortunately, the same procedure on a boat is not safe. Several marinas have well-placed signs to assist with the proper fueling procedures but appear to go unnoticed when we are in a hurry. For proper and safe fueling we:

- 1. Shut off all engines.

This includes the generator. - 2. Shut down all electrical systems.

Both the AC and the DC electrical systems should be shut down. I find the easiest way to do this is to turn off the main battery disconnects, Perko switches and main breaker for AC, and for the inverter if you have one. Doing this prevents the possibility of an electrical spark igniting fuel vapors. - 3. Before you start adding more fuel, know how much is currently in the tanks and have an idea of how much room there is for more.

If your boat holds 200 gallons and the gauge shows half-full, then you can expect to add less than 100 gallons to bring the level near 100%. If you add more than expected, understand why. Was the fuel level gauge inaccurate? Did fuel actually go into the tank that I intended or somewhere else? Is the tank the capacity that I think it is? - 4. Extinguish all open flames.

This includes not only the obvious smoking material but also any gas heaters or barbeques that you have recently used and still may be hot. - 5. Close all portholes, hatches and doors and have all passengers disembark.

When we add fuel to the tanks, air is vented to the atmosphere thru the tank vents. In the case of gasoline these vapors are explosive and can find their way into confined spaces. - 6. Discharge any static electricity from the nozzle by making contact with the fill plate.

The fill plates should be electrically bonded to the vessel’s ground system and will safely discharge any static electricity. During fueling, be certain to keep the nozzle in contact with the plate. It is also important to know which fill is for which tank. I have fueled boats with as many as six tanks and the same number of fill pipes and vents. Fill pipes for water and holding tank pump outs on many boats look the same. Do not put fuel into the wrong tank. - 7. Maintain control of the nozzle as you fill.

I have been to some fuel docks that will terminate your fueling if you do not hold onto the fill nozzle at all times. Some boat designs have the fill plates installed almost vertically and the nozzle is not secure by itself. Many of the fuel nozzles will not automatically shut off and fuel will spill out the vent or out the fill pipe. Listen as the tank fills, you can hear the sound change as the fuel tank nears full. - 8. Don’t overfill.

As fuel warms it expands. The tank vents on most designs are lower than the fill pipe, so it is possible to spill fuel from the vents if you try to squeeze in as much fuel as possible. As a general rule, fuel only to 95% of capacity if your intended voyage plans allow. - 9. Check the vent.

As you fill the tank with fuel, air can be heard or felt exiting the vents. If it is not, then the vent may be clogged, the vent is not connected, or you are not putting fuel in the tank. I have actually seen several instances where the vent has been filled with debris and not venting, making fueling very slow. Also, know which vent is for the tank you are filling. - 10. Safety check.

Once fueling is completed, and before anyone gets back on board, you should do an engine room check. Look for any liquids in the bilges and smell for the odor of fuel. Just a few weeks ago I fueled a boat with a client and due to a cracked fuel hose, we found several gallons of fuel in the bilge after fueling.

Owners of boats with diesel engines will often times skip items one and two and leave the engines running and the vessel powered. Most commercial fuel docks and boat operators do not find this practice to be a safety hazard since diesel fuel is not aromatic at room temperatures and cannot explode. It is your call; personally, I keep the diesels running but have complied with a request from a fuel dock attendant to shut them down.

Lessons Learned

Stay tuned in the next few months for part II of this feature on Fuel Management. Until next month please keep those letters coming. Remember I love a good story. Have a good story to tell, send me an email. patcarson@yachtsmanmagazine.com