Lessons Learned – by Pat Carson

Fuel Management – Part 2

This is a continuation from Fuel Management Part 1 published in the September issue of Bay & Delta Yachtsman. If you missed it, Part 1 can be found online at:

https://www.recreationpublications.com/PUB/baydeltayachtsmansept2024.

This month we will look at other aspects of fuel management that are equally important, such as how much fuel do we have? How much fuel do we burn? How much fuel is in each tank? And how do we move it between tanks? As we discussed in Part 1, to have fuel to manage we must first get fuel into the vessel’s tanks and that begins with knowing where the fuel fill deck plates are located, how many are there and what product goes in there.

Be incredibly careful with this setup, three deck plates in a row with one water and two diesel fills these can be easily confused if in a hurry. Someone not familiar with your vessel could make a big mistake and put water in the fuel or fuel in the water. Also, note that there is a similarity of appearance with gasoline deck fills as well as those used for water and diesel. Several years back I received a call from a client that had made a huge mistake by putting gasoline in his diesel fuel tank and then starting and running the engines until the turbocharger blew apart and black sooty smoke was visible from the engine room vents. His claim was that his brother-in-law put 40 gallons of gasoline into a 300-gallon diesel tank before the error was caught. They then filled the tank to 100% capacity with diesel and decided to run the boat thinking that the ratio of gasoline to diesel was small and would not harm the engine. Apparently, his Volvo engine ran pretty good for a while as when he called us to rescue the yacht, we found it laid up in Benecia. We then had her towed back to Stockton where we removed the contaminated fuel and refilled the tank with clean diesel. An expensive error in judgement, not to mention the new turbo, exhaust hose and extensive engine room cleaning that were required. I asked around my many contacts of experienced mechanics and none of them could give me a definitive answer as to what percentage of gasoline can be mixed with diesel, or diesel mixed with gasoline before engine damage occurs. It appears that ten percent is too much and that zero percent is likely much better.

Even an experienced yachtsman or fuel dock attendant can make a mistake, so it is always good practice to ask the attendant if he is handing you a diesel (or gasoline) hose, and if it is a boat you are not familiar with double check that the filler cap on the boat matches the product about to be dispensed. On the street, most all the diesel hoses and nozzles are color coded green, but this is not the case at marine fuel docks. Do not rely on the color of the hose or nozzle matching the product. Listed in Part 1 were the ten steps to safe fueling. I listed step three, “Before you start adding more fuel, know how much is currently in the tanks and have an idea of how much room there is for more.” And it should be amended to make certain that you are dispensing the correct product into the correct hole.

No discussion on fuel management is complete without covering fuel contamination; whether you have gasoline or diesel propulsion, contaminated and old fuel can be problematic. Left untreated, no refined petroleum fuel is stable for extended periods of time. Although diesel is better than gasoline it has an untreated stable life of 12 months or so while untreated pump gas is good for only a few months. The new renewable diesel is much better, and I have seen some claims that it is stable for up to 24 months even if untreated. I always like fueling other people’s boats and just watching as the numbers spin and the dollar totals reach towards the stratosphere. The best part being that when the tanks are full, I just finish and do not have to make that long walk to the office with my credit card in tow. Although fuel costs are high, I believe that when we total all the costs associated with our chosen recreation of yachting, what we spend on fuel is a small part of the total. Purchase the best product available and maintain it until it is consumed.

The gasoline we put in our boats is usually the same 10% ethanol blend that we put in our cars. Ethanol is soluble in gasoline only if the alcohol is very dry, but unfortunately, the mixture is hygroscopic, over time drawing water from the air. In addition, the ethanol blend can become unstable when the temperature drops. During the day as the temperatures rise the vapor pressure increases, as the temperatures cool, more humid air is drawn into the tank every night. A half-full tank of untreated gasoline can become moisture saturated in 30 to 90 days, depending upon the temperature range and humidity. This moisture saturated gasoline is now susceptible to phase separation, corrosion and stability problems. Not such an issue in a car as we generally use the fuel within a month or so, whereas in our boats that fuel may sit for many months. In marine use we see a lot of gasoline fuel related problems that could have been prevented by storing with the fuel tanks full, adding a fuel treatment when fueling or by using a marine grade ethanol free fuel such as Valvtect. It is also important to keep the gasoline fuel filters clean, and if the vessel’s fuel system incorporates a fuel/water separator that it is kept clean and free of water. A fuel filter used past its serviceable life will cause poor engine performance and possibly engine damage.

Many mariners are aware of the issues with ethanol blended gasoline but think that diesel is stable and can be stored for extended periods without degradation. Depending on where you are purchasing marine fuel, you may be purchasing any one of four diesel products, each with their own special instructions. In Canada I have seen both B5 and B20 biodiesel sold at the marine fuel docks. While these blends of either 5% or 20% biodiesel are derived from vegetable oil, animal fats or cooking grease mixed with petroleum diesel claim to have lower emissions and improved fuel economy, my experience is biodiesel in any mixture is nothing but problems and should be avoided.

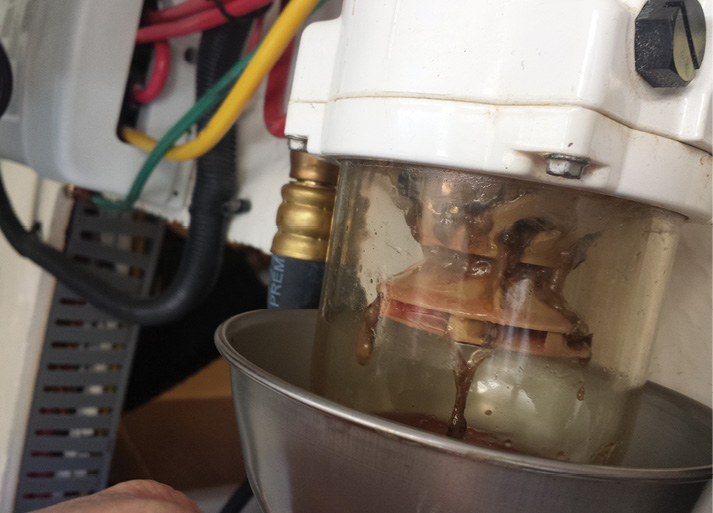

I recently moved a boat from Canada to San Francisco that had been fueled exclusively (the owner was proud of the fact) with B20 biodiesel, and we almost immediately had issues with a plugged primary fuel filter and poor engine performance. While perhaps not much of an issue in calm waters, a coastal voyage with a single engine and a single primary fuel filter plugged with a gooey gray slime can be a big problem.

You could visually see the gray slime in the fuel/water separator that got worse with every mile we covered. Unfortunately, this single engine trawler was so fuel efficient we could not burn off the crappy fuel fast enough and had to stop many times to replace the filter and drain the slime from the bowl.

This went on for several days and required that we stop at every fuel dock, drain the bowl, change the filter and add new diesel to the tank. My suggestion is to avoid biodiesel at all costs. I will not even put biodiesel in my truck!

Pure #2 diesel is my second choice for marine fuel. This product is widely available and can be trouble free if some basic precautions are taken. History tells us that clean diesel #2 can be safely stored for up to a year if treated with a good additive such as AMS Oil Diesel all-in-one fuel additive (my preferred) or STA-BIL Diesel fuel stabilizer. Most of us are familiar with the potential problem of bacteria and fungi growth in a tank of untreated diesel, but this only occurs in the presence of water. You must first get moisture into your diesel tank before algae can grow, but when it starts it can be a real problem.

Water can enter the fuel tank through condensation, leaks or improper storage; prevention is the key here. Add the fuel treatment at every fill up and keep the tanks full for long term storage.

Renewable diesel – a cleaner alternative is my first choice by a long margin. Although renewable diesel is a biofuel, unlike biodiesel it is produced only from vegetable oils and the process is quite different from that of biodiesel. Renewable diesel is produced through a process called hydrotreating, where the feedstock is heated under pressure in a hydrogen environment that removes impurities and oxygen from the feedstock. This results in a fuel that is chemically similar to petroleum diesel but burns cleaner with less pollutants such as nitrogen oxides, NOx. In California particularly, R99 (99% renewable and 1% petroleum) have become ubiquitous both on the road and on the water. Although renewable diesel is susceptible to bacterial and fungi growth like petroleum diesel, manufacturers of renewable diesel such as Neste claim that untreated it can be safely stored for up to two years. While the cost of renewable diesel is higher than petroleum diesel, it does provide better fuel economy due to its higher cetane level, reduced engine wear due to its cleaner burning properties and has fewer greenhouse gas emissions.

Any diesel fuel, if improperly stored or stored for extended periods of time, can and will develop biological growth in the presence of water. Once the fuel becomes contaminated the best course of action is to filter it, a process commonly referred to as polishing the fuel. Fuel polishing is really nothing more than running the fuel through a series of progressively finer filtration until all the contaminants have been removed and only pure dry fuel remains. In a marine diesel engine, you are effectively polishing the fuel all the time since our engines only consume around 25% or so of the fuel pumped. Take an example of a modern diesel engine that burns ten gallons per hour, the fuel system may be supplying 40 gallons per hour with the extra 30 gallons per hour being returned to the tank after passing through both the primary and secondary filters. In most cases, if there are contaminants in the fuel you may be changing the filters often and draining the fuel/water separator regularly, but eventually all the fuel will be either filtered or burned. In extreme cases the services of a fuel polishing and tank cleaning specialist may be required to make the fuel usable.

On a recent boat delivery, we started having fuel problems after nearly 150 miles of trouble-free operation. Our first indication of fuel issues came during a routine engine room check where we saw the fuel system vacuum gauge reading worrisomely high.

A system vacuum greater than five PSI requires immediate servicing, a vacuum of 12 PSI as indicated means impending system failure, which it did before we could shut down the engine and change the filters. In this particular case we kept getting high vacuums in shorter intervals and made the decision to find a safe harbor and arrange to have the fuel polished.

Unfortunately, it turned out that the problem was not only contaminated fuel, but contaminated fuel tanks as well. Once the bacteria and fungi growth start and are not addressed for a prolonged period, the green slime sticks to the internal sides of the tanks and must be cleaned with access holes cut into the tank.

The quantity of sticky green algae that was removed from the primary fuel filters, fuel/water separator and fuel line was amazing. Add another bucket of growth removed from the tank internals and you can understand why we had fuel delivery issues.

By now you are thinking I am glad that I have gasoline engines and do not have to deal with these diesel fuel issues. Right and wrong. Gasoline will not allow algae to grow as does diesel fuel, however gasoline will deteriorate over time. Exposure to oxygen can cause gasoline to break down and form gums and varnishes. Water, dirt and other contaminants if allowed to enter the tank will accelerate this deterioration. Remember, ethanol blended gasoline will start to phase change after a few months at best. The ethanol is blended to increase the octane of the gasoline, and when separated you are left with extremely low octane fuel that will damage your engine. Your only solution with bad gas is to remove the fuel and dispose of it properly – a job best left to a professional as gasoline vapors are explosive and there is a real danger in attempting this without the right equipment.

Lessons Learned

In Part 1 I covered how to manage the fuel that you have on board, either by setting a series of manual valves or by transferring fuel between tanks with an electric pump. Understanding how to move fuel around on your vessel is important for voyage planning. This month in Part 2 I hope your takeaway is how important it is to use an excellent quality fuel and to store it properly. Fuel problems are rare and almost always start with owner neglect.

And a final word about bilge or engine room blowers. I have been with clients doing the safe fueling drill and have been asked if we should run the blower for five minutes after fueling and before starting the engines. I answer that question with why? If we have done a safety check, then we know that there are no fuel vapors below decks and the engines are safe to start. Running the engine room blowers is not a substitute for going into the engine room and other enclosed spaces where the fuel tanks are located to look and sniff for fuel vapors. Bilge blowers are designed to exchange air in the enclosed engine room space that potentially may contain fuel vapors. Many diesel-powered boats do not even have engine room blowers due to the inherent safety of diesel fuel. In the interest of safety, I do turn on the blowers after closing up the engine room, but make it a practice to give a quick sniff of the air coming out the vent. This air should not have any fuel smell to it and again indicates that there are no flammable vapors below decks. Start your engines and enjoy the time on the water.

To start out 2025 my January piece will be “Is It Right or Is It Wrong”. If you have a good photo or two that you would like to share, please send high resolution photos by email and I will include them. Now it is time for me to walk away from the fuel dock, light up my cigar, pour a glass of fine port and look around the marina for more examples of is it right or is it wrong. Until next month please keep those letters coming. Remember, I love a good story. If you have a good story to tell, send me an email at patcarson@yachtsmanmagazine.com